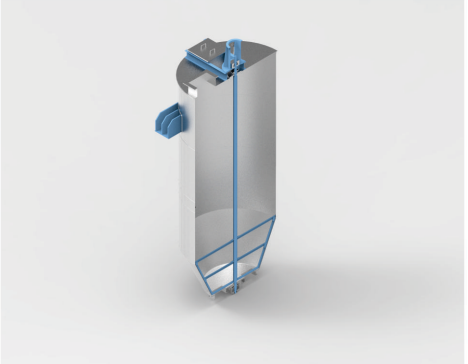

Dense Tank Agitator

Let’s Mix It Right

Need help selecting or customizing a Dense Tank Agitator for your process? Our engineering team will evaluate your slurry properties and recommend the right solution — built to perform and last.

Need help selecting or customizing a Dense Tank Agitator for your process? Our engineering team will evaluate your slurry properties and recommend the right solution — built to perform and last.